AUGUSTA — The region’s newest hospital is about one-third complete and construction is moving along rapidly.

Builders are taking advantage of cost- and time-saving methods by prefabricating exterior panels and interior bathroom shells as well as frames which hold medical gas lines, electrical power and in-room monitoring equipment.

John Scott, senior project manager at the site of MaineGeneral Medical Center’s 192-bed regional hospital, said the work schedule incorporates some of the savings gained by prefabricating structures on site.

However, he added, “We’re being cautious in our projections.”

HP Cummings, which has offices in Winthrop, is partnering with Alabama-based Robins & Morton on the construction management.

Scott was reluctant even to give the 30 percent complete estimate as visitors stood outside the rear of the building, which already has its exterior brick facing.

The current completion date projection came from Chuck Hays, president and chief executive officer for MaineGeneral Medical Center.

The $312 million hospital, which is between Interstate 95 and Old Belgrade Road adjacent to the Harold Alfond Center for Cancer Care, is projected to open by the end of 2013, about six months earlier than originally anticipated.

“What we’re targeting is the beginning of December 2013,” Hays said. “Until we have the building weather-tight, which should be by the end of this summer, then we can come up a more firm date.”

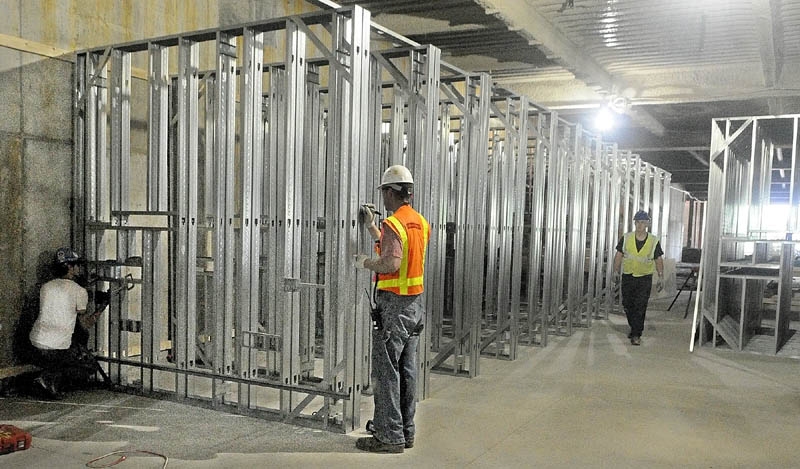

Prefabricating for fittings for patient rooms takes place on the first floor where racks of metal frames for the equipment headwalls destined for each patient room stand against one concrete wall.

Studding for the headwalls that stand behind the 192 patient beds begins at Porter Panel & Truss, a division of Porter Drywall in Portland, and the frames are shipped for finishing at the hospital.

Ivan Stevens, also of HP Cummings, who oversees the prefabrication on-site prefabrication, said workers — generally a crew of two electricians, two plumbers and one carpenter — turn out three or four headwalls a day, and have been working on bathrooms also for the past several weeks. A dozen of those were in various stages of being fitted out.

They have sliding doors instead of swinging doors and European showers without a threshold, making them compliant with the Americans with Disabilities Act.

“The amount of labor it takes doesn’t change, but doing the work ahead of time shrinks the schedule,” Scott said. “We can be sheet-rocking a room much quicker.” He said prefabrication allows for continuous improvement as well.

New rooms

Rooms in the new hospital will differ from those at the two in-patient hospitals operated by MaineGeneral Medical Center in Augusta and Waterville because all the beds will be in private rooms, and each room will be fitted with a patient-lift device and have a sofa or chair that converts into a bed so someone can stay with the patient.

Several of the convertible furniture options were arrayed around a large conference room at construction headquarters. And soon, a mockup of one of the new hospital’s patient room will be set up at the Seton site in Waterville.

Hospital spokeswoman Diane Peterson said that will allow hospital staff to see what the new rooms will be like.

The new hospital is designed with a main corridor for public use at the front of the building and a more private, rear corridor for patient transport and service areas.

The interior of some sections of the hospital already divides into corridors, rooms, courtyards, and penthouses with mechanical equipment.

Several people easily could walk abreast in the ductwork running through the mechanical equipment penthouse that serves the 10 operating rooms.

“They need a lot of air changes,” Scott said. Several of the operating rooms are larger than the standard 600-square-feet and the extra room will allow them to “embrace technology.”

“You try as much as you can to make provisions for the future,” Scott said.

The skeleton for the first of two patient towers — the one that will house material and child health and intensive care units — is almost complete and the footprint for the second tower, which will house medical/surgical patients, awaits the steel installation, which is expected to begin this week.

Getting busy inside

Scott rattles off the stages of each phase: base, steel, deck, concrete, exterior walls, roof, interior.

Pads at the rear of the hospital hold a cooling tower and three generators. A cradle awaits the a propane tank that will supply fuel until a natural gas line comes through.

“We’re looking forward to the natural gas line,” Scott said. Because of the anticipated chance, the fittings will accommodate both propane and natural gas.

“The dual fuel system gives the hospital flexibility in the future,” he added.

Windows were being installed near the first-floor main entrance to the building and a large courtyard in one section of the building allowed daylight to shine below ground level where the labs and pharmacy will be located.

Last week, the inside of the hospital building appeared even busier than the outside.

Drywall installers, plumbers, electricians fitted out the behavioral health area, and several bathrooms there awaited drywall. Some of the units still rested on the wheels that are used to guide them in place in the rooms.

Workers were hanging sheetrock in the imaging area.

“We’re really only a few weeks from painting,” Scott said.

Once the second patient tower is erected, work will begin on the cafeteria area, which will have a walk-out terrace area overlooking a pond with a fountain in it, similar that already in place at the Harold Alfond Center for Cancer Care next door.

A spiritual space also is included on the terrace level as well as a garden area.

Betty Adams — 621-5631

badams@centralmaine.com

VIDEO ONLINE

To view video of the latest construction work, visit kjonline.com

Send questions/comments to the editors.