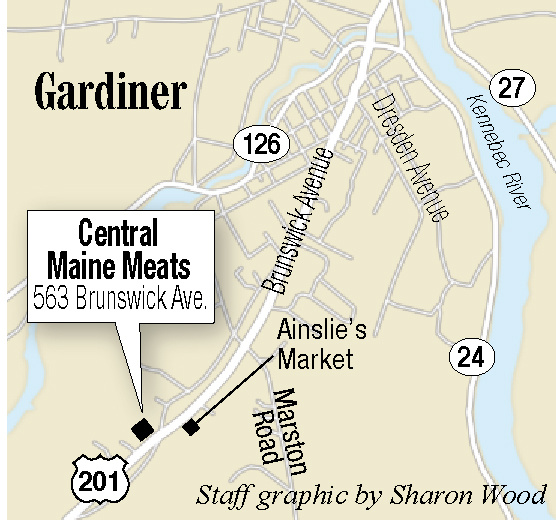

GARDINER — The flash-freezing tunnel that Central Maine Meats uses in its Brunswick Avenue facility is relatively small by industry standards, but it is mighty.

It can flash freeze up to 3,300 hamburger patties a day, and that’s the technology that the owners of the Gardiner-based slaughterhouse see as the key to preserving Maine agricultural products — including fruits, vegetables and seafood — for year-round consumption in Maine and anywhere else the food can be shipped.

“Can you imagine sitting in California and ordering up a lobster tail and a steak to be flash-frozen and overnighted?” Bill Lovely, co-owner of Central Maine Meats said Monday.

It’s within the realm of possibility, but it’s not the only opportunity out there.

“This has been a long time coming, and it’s going to do tremendous things for Maine. It’s really, really important to producers,” said Lisa Webster, founder and farmer at North Star Sheep Farm in Windham and president of the Agricultural Council of Maine.

Webster already sells her lamb products to Whole Foods for its New England stores and at Hannaford supermarkets — currently three but soon to be 46.

One of the distributors Webster works with is Native Maine Produce and Specialty Foods in Westbrook, just a handful of miles from her farm. But to get her processed lamb there, she would have to take her animals to western Massachusetts, southwestern Vermont or southeastern New York for processing first, adding transportation and time expense.

“It’s insane, and it’s not just me,” she said. Pork and beef producers face the same hurdles.

Webster has been seeking feedback from her customers on the lamb patties and sausages that Central Maine Meats has flash-frozen for her, and the response has been positive, she said. That’s opened the door to developing more than a dozen additional products, such as seasoned lamb sliders and patties.

“The infrastructure is considerable, but we’re very pleased with how things are going,” Joel Davis, managing director of Central Maine Meats, said.

Central Maine Meats has the ability to make up smaller packages, which opens up markets at small, local retailers and co-ops, she said. The company also has the capability to use stock keeping units (SKUs) and bar codes, allowing meat to be traced back to the farm of origin.

“We are demanding an awful lot from them,” she said, but they are also getting a lot. With this added service, she’s going to be able to add more distributors for her products and extend her market reach.

The tunnel, manufactured by Matheson Gas, is essentially a large metal box that uses nitrogen dispersed by fans to freeze any item that’s carried through the freezing chamber on the machine’s conveyor belt. Freezing is controlled by the temperature set on the machine, the length of the conveyor belt and the time it takes an item to make its way through the chamber.

The flash-freeze technology preserves freshness by sealing in moisture. The items that are frozen don’t stick together and when they thaw, they don’t suffer from the cell breakdown that traditional freezing can cause. What would take an air-cooled system anywhere from 12 to 24 hours to freeze, a flash freezer can process in a handful of hours.

Plans have been in the works for a large-scale flash-freeze facility at the Libby Hill Business Park since before the middle of last year, when the Gardiner Planning Board approved the company’s proposal.

“It’s licensed and permitted,” Davis said. “The original plan was for the latter part of this year, but it depends on when we get it all operational.”

Davis anticipates having five or six tunnels, ranging in size from 18-20 feet long to 40 feet long.

In the meantime, Central Maine Meats employees are learning the technology and using the 12-foot tunnel at the Brunswick Avenue facility to fill orders and preserve meat.

“The question is, can we scale the food opportunity to such a scale that agricultural producers come to our facility?” Davis said.

That’s going to take some education and outreach, and part of the company’s plan to accomplish that is to take its products to people.

In February, the Gardiner City Council agreed to a request by Davis to use $1,000, matched by $1,000 from the company, to market Central Maine Meats products, as well as those of other organizations tied to the local foods movement, at the Classic Car Cruise-In in Gardiner, which this year will be held at the Gardiner Waterfront Park starting in May. The city’s share of the funding came from the 1 percent administration fee that came from the company’s $100,000 Workforce Development Grant secured last year.

“We want to make it open to others in the local food realm,” Patrick Wright, economic development coordinator for Gardiner, said. “Folks who are interested in taking advantage of the opportunity can contact us.”

The first drive-in is scheduled for 5 p.m. on May 5.

“We’re going to cook some product and let people sample it,” Lovely said.

Jessica Lowell — 621-5632

Twitter: @JLowellKJ

Send questions/comments to the editors.