BELGRADE — Making maple syrup can be a lot of work, starting with the collection of sap, hauling the sap from the trees to the sugar shack and waiting hours for the sap to boil down into syrup, but luckily Gil Whitehead has help doing it.

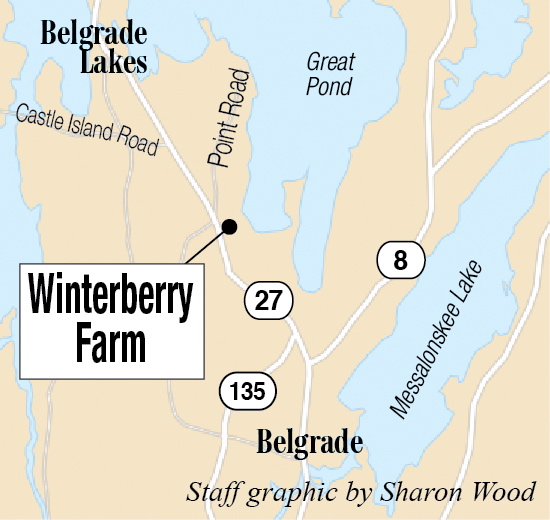

Red and Star — a pair of 5-year-old oxen — are the constant companions to the 15-year-old as he goes about the task on his family’s farm, known as Winterberry Farm. The oxen play an important part in transporting the sap, which is collected from metal buckets and transferred to a 5-gallon container that they pull on a sled.

“They’re a big help. I use them for everything,” Gil told some of his classmates from the Maine Academy of Natural Sciences on a recent morning at the farm. It was one of three maple syrup producing operations that students from the Fairfield charter school visited to gain a better understanding of the maple syrup making process, which they’re also working on at the school’s campus.

The 40-acre Winterberry Farm produces about 5 gallons of maple syrup each year, just enough for the family’s own use — which includes Gil, his mom and his younger sister, Sage. But making maple syrup is a laborious process that requires about 40 gallons of sap to make 1 gallon of syrup, Gil said as he led Red and Star along a snow-covered path leading to a cluster of maple trees.

The sap collects in buckets attached to the trees and is transferred to a larger container that the oxen pull. At that point, it’s so diluted it looks just like water. While Gil gathers the sap, Red and Star paw the ground looking for any nibble of grass they can find under the snow and scratch their heads on sapling trees.

The farm has no tractors or machinery, a decision farm owner Mary Perry attributes to her love for horses. “I find it easiest to do what you’re familiar with, and I’ve never known a lot about tractors or machinery, but I grew up loving horses,” Perry said. “We just prefer animals. They’re quiet, and it’s something I’m familiar with.”

A few years ago the family acquired the oxen, whose job around the farm is not limited to hauling sap. Their also used for hauling wood and vegetables and spreading compost. Their impact on the soil is low and they don’t require fossil fuels to run, Perry said.

“As a small farm, it works for our production level,” Perry said. “I don’t know if it would be as practical on a larger farm, but it works for us.”

The sap collected by Gil and pulled by the oxen is placed over a wood stove and boiled down to maple syrup — a process that takes most of the day. As his classmates get in the school’s vans to head back to campus, Gil stays behind to finish the maple syrup. As part of a special arrangement at the school, he’s able to get credit for the project. He’ll also work on a presentation on the process and history of maple syruping.

“I think they liked getting a chance to be around a working team of oxen and see them working. I don’t think a lot of them have ever seen a team of oxen,” Gil said of his classmates.

The farm is one of a few variously sized maple syruping operations that students from the charter school visited recently. Although the school has its own sugar shack on the Good-Will Hinckley campus, visiting Winterberry Farm was a good way to expose students to a small-scale maple syrup operation, said Dylan Engler, a humanities teacher.

“I liked the number of different animals around here,” said Seth Theriault, 15, of Winslow, a student at the charter school. In addition to the oxen, the farm has horses, chickens, Bourbon Red turkeys and sheep. “It’s pretty awesome,” he said.

Rachel Ohm — 612-2368

Twitter: @rachel_ohm

Send questions/comments to the editors.