SKOWHEGAN — Sappi Fine North America will invest $25 million over the next year on new equipment in the paper company’s wood yard on U.S. Route 201 in Skowhegan, adding as many as 100 temporary construction jobs.

The investment, coupled with a $60 million capital investment in equipment and environmental safeguards already put into the Somerset plant since 2011, means the South African company is committed to the region for the long haul, mill managing director Tony Ouellette said Thursday.

Vendor bid requests will be going out over the next two weeks and work is expected to begin in October during the annual mill shutdown and continue for most of 2017, with a conclusion date of November 2017. He said 50 to 100 temporary construction jobs could be added during construction and installation of the new equipment.

The investment will allow the company to modernize its wood debarking, chipping and chip distribution systems in the woodyard on U.S. 201 in the south end of Skowhegan. The changes will improve reliability, reduce white wood losses and costs, and add efficiency through increased wood chip production, according to a company news release.

“This is really positive news for both the Somerset mill and the community,” Ouellette said in a conference call Thursday. “It’s reaffirming our commitment and the company’s commitment that we’re going to be here for the long haul. It helps our efficiencies; it helps our ability to compete with a very difficult market and certainly is going to help us maintain our standing as the flagship mill in North America.”

Skowhegan Town Manager Christine Almand said news of the company reinvesting in its Somerset operations bodes well for the future.

“I’m delighted that Sappi continually invests in the mill,” Almand said. “Investment and innovation are the keys to staying viable. Sappi has a good grasp on this and has taken steps to position themselves as leaders in the paper industry.”

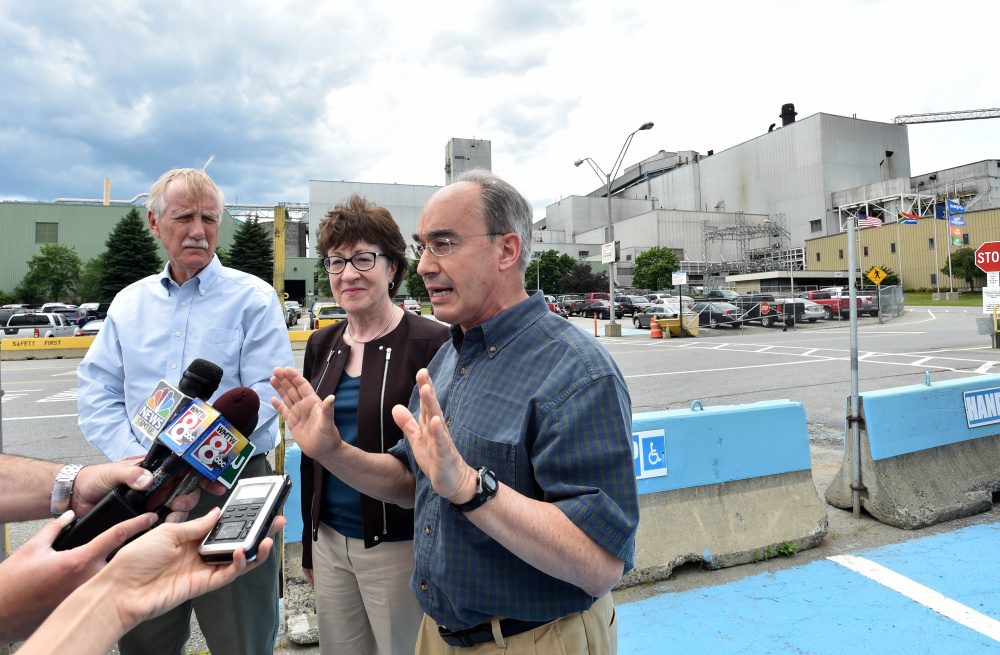

Maine’s U.S. Sens. Susan Collins, a Republican, and Angus King, an independent, and U.S. Rep. Bruce Poliquin, R-2nd District, praised the project in a joint statement.

“This announcement is welcome news for Skowhegan and for the men and women of Maine’s forest products industry,” they said. “We recently visited Sappi’s Somerset Paper Mill and saw their impressive manufacturing facility and encouraging model of innovation that converts Maine trees into products that can be used around the world. This investment, coupled with the work of the multiagency Economic Development Assessment Team visiting Maine in mid-August, will help create and maintain stable, good-paying jobs and help ensure that the forest products industry has a strong future in our state.”

Sappi’s Somerset mill, built in 1976, has three paper machines and employs 750. The company also has a mill in Westbrook. The town and the company struggled over tax value as the mill’s revenue declined, but they reached a compromise in March that both sides said would save jobs while still helping the town’s tax base.

Megan Sanborn at the Maine Pulp and Paper Association did not immediately return messages Thursday asking for comment on the $25 million wood yard upgrade.

The announcement this week comes during a decline in Maine’s paper-making industry, including nearby Madison Paper Industries’ closing in May, putting 214 out of work.

Madison was the fifth paper mill in the state to close in the last two years, a situation that Collins and King called an “economic crisis.” There are six operating paper mills left in Maine, down from 11 in the 1960s.

The two, with Poliquin, announced last week that an Economic Development Assessment Team created by the Department of Commerce to help the state’s forest products industry will visit this month. The goal is to help the state come up with a long-term economic plan, including nearly $8 million in grants to help related organizations build a “sustainable economic future” for the industry.

The three members of the state’s delegation visited the Sappi mill in July, where King said the Skowhegan mill is “working hard and making progress.”

Members of the delegation used the mill as an example of how the forest products industry in the state still can succeed despite recent setbacks.

“The demise of the paper industry in Maine has been grossly exaggerated,” King said during the visit.”

Sappi and Skowhegan have worked to keep the mill a sustainable factor in the town of about 8,500, where it is a major employer and taxpayer.

The agreement capped the mill’s taxation value at $380 million, and Sappi agreed to withdraw tax abatement requests against the town for 2014 and 2015, putting an end to disagreements about the mill’s valuation that had lasted for months and reduced the mill’s taxation value for the coming fiscal year by $64 million. Under the agreement, the town will lose about $1.2 million in taxes for fiscal year 2016-17.

Town assessors will update the property valuation in coming years, but it’s not to exceed $380 million in 2017-18 and 2018-19. No abatement will be sought by Sappi, and there will be no supplemental assessments for taxation by the town.

Laura Thompson, the company’s director of sustainability, said in May that the company is committed to keeping jobs in Skowhegan. Sappi’s sustainability report, released in May, said the company concentrates on environmental issues, social issues — including jobs — and economic issues.

Of the 750 workers at the Somerset mill, 180 are salaried employees. The rest are hourly-wage workers represented by four labor unions. The Somerset mill produces 795,000 metric tons of coated paper annually and more than 500,000 metric tons of pulp annually, according to Ouellette.

Sappi North America has been producing LusterPrint, a grease-resistant paper used primarily for pet food packaging, since 1993; and last year it expanded the line to include a new paper called LusterCote at the Skowhegan mill.

The launch of the new paper line was a key facet in the company’s decision to expand production of packaging materials, officials said during the delegation’s July visit.

The mill was certified in August 2011 by the Center for Resource Solutions Green-e Energy Marketplace program for its $49 million capital investment in renewable energy generation. Another $11 million was infused in the following year.

Investments included upgrades to the pulp mill’s recovery boiler and related equipment. Under the Green-e certification, 100 percent of the electricity used to manufacture Sappi’s trademark Opus web paper at the Somerset mill is certified renewable energy. Green-e is the nation’s leading, independent, third-party certification and verification program for renewable energy, ensuring that strict environmental and consumer protection standards are met.

Sappi Fine Paper North America was named the 2012 Maine Manufacturer of the Year by the Maine Forest Products Council.

Company officials also acknowledged in May a list of the biggest polluters in Maine released in 2014 by the federal Environmental Protection Agency that included the Sappi mill in Skowhegan, which was listed third in the state, with more than 2 million pounds of toxic chemicals emitted. The company’s Westbrook operation also made the list as the state’s eighth-largest polluter, with about 257,000 pounds of emissions, according to a published report.

Sappi President and CEO Mark Gardner and Thompson acknowledged the pollution data, noting that reducing toxic emissions is among the top goals of the company. Gardner said in May that the conversion to energy-efficient practices over the past few years to reduce pollutants has led to the reuse of waste byproducts in the paper-making process.

“Over the years, Sappi has invested tens of millions of dollars in pollution control equipment, and we are in full compliance with all relevant federal and state laws, with Maine having some of the most stringent laws in the country,” Gardner said. “In some cases, we are well ahead of aggressive goals; and in some areas, we will need to dig a little deeper and work harder to achieve our five-year vision.”

Ouellette on Thursday echoed Gardner’s concern.

“That is certainly one of our main goals that we strive for every day,” he said Thursday. “I can’t speak highly enough of Laura Thompson and the work she has done in our sustainability footprint to ensure that we keep the emissions well within all the regulations and certainly with the focus of reducing it whenever we can.”

Doug Harlow — 612-2367

Twitter:@Doug_Harlow

Send questions/comments to the editors.